Patient Specific Instrumentation

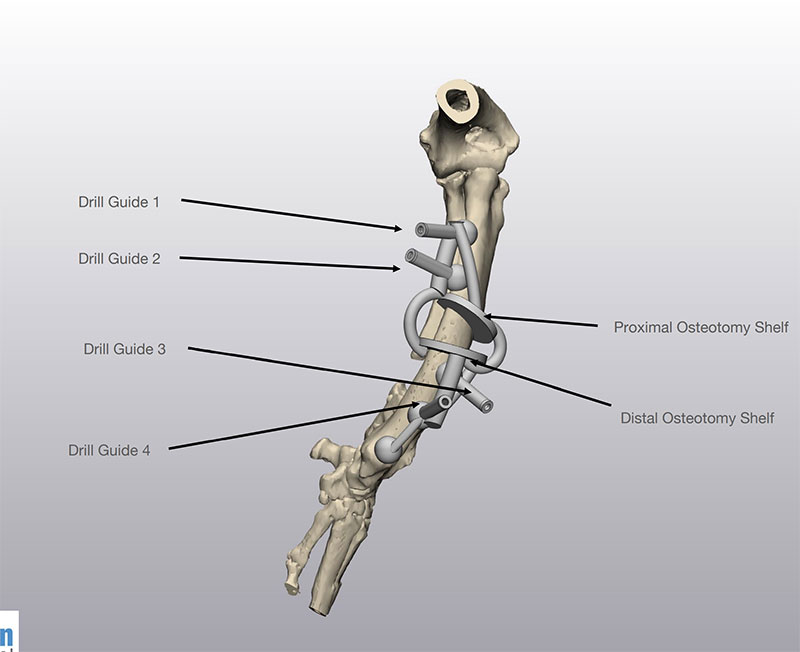

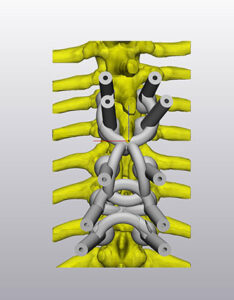

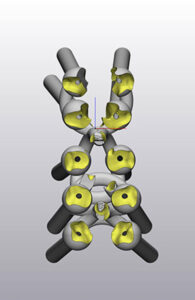

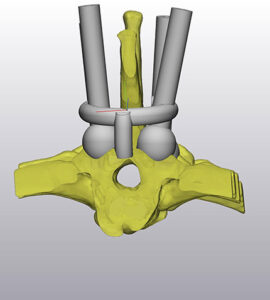

Custom 3D printed bone models and guides have changed the way orthopedists perform complex surgery. The most common application is use of osteotomy and reduction guides to facilitate deformity correction with a high degree of accuracy. This accuracy has expanded the use of internal fixation over bulky external skeletal fixation, even for the most challenging of angular deformities. The Cartesian Medical team also has extensive experience in design and use of custom guides for arthroplasty, spinal surgery, fracture repair, and oncologic limb-sparing techniques.

- Our guides are delivered in a set of two copies (additional copies available upon request), allowing the clinician to plan and rehearse the surgery. Rehearsal has utility in identifying surgical challenges and prepares the surgeon to meet these challenges. Implant selection and contouring may additionally, the CM team be performed using the models, ensuring a more efficient surgery.

- Bone models are printed using a fused deposition modeler (FDM) printer. The bone material is a micro carbon filled nylon which results in a strong, smooth finish that is easily cut by surgical saws.

- Surgical guides are made of biocompatible resin printed using a steolithography (SLA) printer. Guides are made with the underside surface conforming to the unique topography of the bone, allowing easy and accurate guide placement. Guides are secured to bones using wires or pins.

- Models are made through detailed segmentation of bone from CT and DICOM images. Click here to start a consultation for 3D printed bone models

- Sterilization options include steam autoclave and ethylene oxide gas.

- To start a consultation for 3D printed bone models and guides